Treesoft Cad Control Cabinet Heat Calculation

With the Treesoft CAD control cabinet heat calculation, you can perform a heat calculation based on the planned electrical equipment and the selected control cabinet. Based on the calculation, you can then select the appropriate air conditioning for the control cabinet.

The Treesoft CAD control cabinet heat calculation is an optional add-on module for the Treesoft CAD control cabinet wizard. It is nearing completion and will soon be available for EUR 200. We are happy to take pre-orders so that you can be among the first to use this new add-on module.

Below, we would like to share with you the development of the control cabinet heat calculation. We invite you to use the form to provide constructive criticism and let us know if you have any suggestions for improvement.

New add-on module is about to be released

We assumed that you would perform the heat calculation and climate control of control cabinets using one of the many tools available on the market, such as RiTherm from RITTAL GmbH & Co. KG.

In practice, however, it has been shown that the use of these tools often fails due to the effort required to determine the power loss of the individual operating resources.

actual analysis

We then quickly analyzed what data we already had in Treesoft CAD.

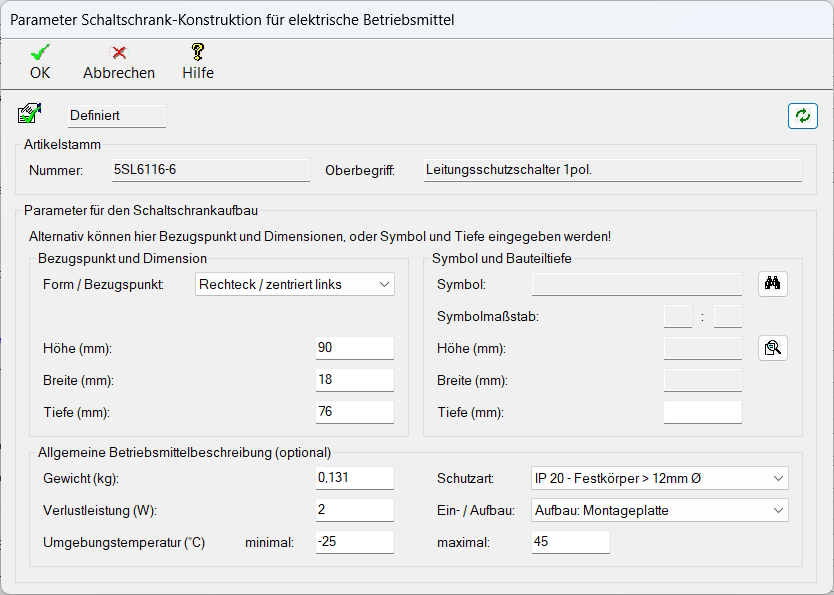

Parameters for electrical components

When editing the parameters for the electrical components, you can enter the following data.

We already have everything we need. The power loss and minimum and maximum ambient temperatures—what more could you want?

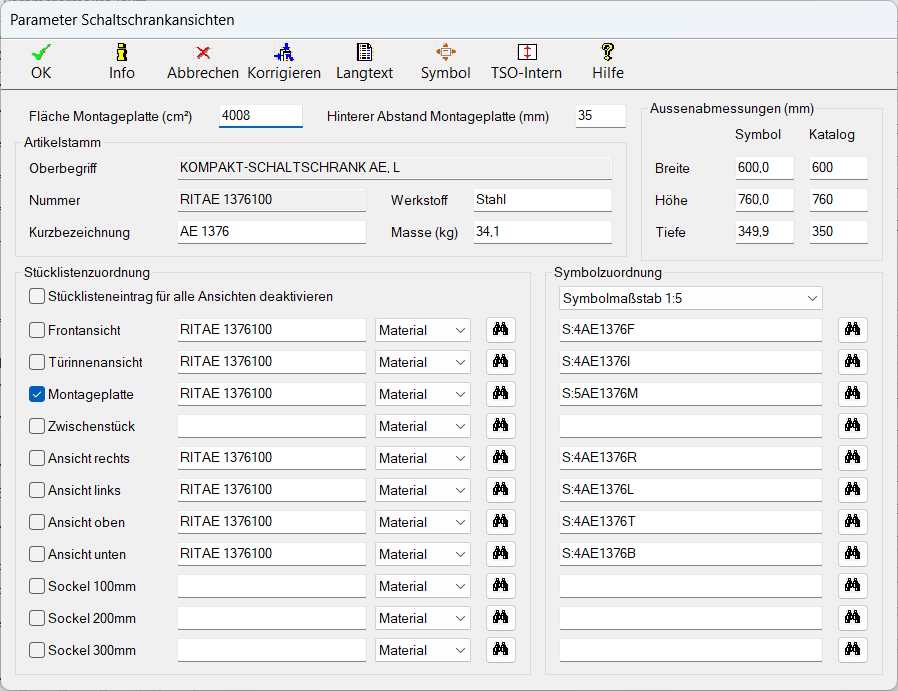

Parameters for the control cabinet

The material, mass, width, height, and depth are stored in the Parameter Control Cabinet Views dialog box. This information is sufficient for the calculation.

Select control cabinet

When selecting a control cabinet, you can use the Symbol function in the catalog tree to display the long text if desired. This contains all the information you need to make the right selection.

concurrency factor

Then we looked at the simultaneity factor. This indicates the probability that all consumers in a system will operate at full capacity at the same time on average. We found the following table for this purpose.

Values for the assumed load

| main circuits | Assumed stress factor |

|---|---|

| 2 and 3 | 0.9 |

| 4 and 5 | 0.8 |

| 6 to 9 | 0.7 |

| 10 and more | 0.6 |

Heat transfer coefficients of standard switch cabinet walls

We have also researched this and found the following values:

| A | Painted sheet steel: U=5.5 W/(m²*K) | 05.50 | W/m²*K |

| B | Stainless steel sheet: U=4.5 W/(m²*K) | $4.50 | W/m²*K |

| C | Aluminum: U=12.0 W/(m²*K) | 12.00 | W/m²*K |

| D | Double-walled aluminum: U=4.5 W/(m²*K) | $4.50 | W/m²*K |

| E | Polyester: U=3.5 W/(m²*K) | $3.50 | W/m²*K |

| F | Stainless steel: U=3.7 W/(m²*K) | $3.70 | W/m²*K |

| A | K – Heat transfer coefficient of control cabinet | 05.50 | W/m²*K |

We kindly request your review. Anyone who can contribute to this is most welcome.

Formulas for calculating the effective switch cabinet surface area

Here we have researched the following formulas:

| A | Single enclosure – free-standing on all sides | A (m²) = 1.8 x H x (W + H) + 1.4 x W x D |

| B | Single enclosure for wall mounting | A (m²) = 1.4 x B x (H + T) + 1.8 x T x H |

| C | Start or end housing – freestanding | A (m²) = 1.4 x D x (H + W) + 1.8 x W x H |

| D | Start or end housing for wall mounting | A (m²) = 1.4 x H x (W + D) + 1.4 x W x D |

| E | Center housing – freestanding | A (m²) = 1.8 x B x H + 1.4 x B x D + D x H |

| F | Center housing for wall mounting | A (m²) = 1.4 x B x (H + T) + T x H |

Sources:

Development of a table

We developed a table based on the information determined in the actual analysis.

Our goal is for all red fields to be filled automatically from the parameters stored in the master data, and for the green fields to be calculated automatically from this.

For example, the “maximum temperature inside the control cabinet Ti” is determined by the equipment used with the lowest maximum ambient temperature.

We have currently focused on heat calculation here. If you need to build control cabinets for Alaska, we will expand the formulas and develop a planning tool for the air conditioning of control cabinets. If any of you need this, i.e., if you also need to heat control cabinets, please let us know.

Your task is therefore limited to filling in the yellow fields.

quality assurance

We compared the calculations with the results from different tools, and the results were very promising. There were only very slight deviations of 0.5 °C.

What remains to be done?

Now we need to convert the table into Treesoft CAD dialogs and store the corresponding formulas.

Create form template

Last but not least, we will develop a form, similar to the templates for parts lists or terminal diagrams, in which we would like to output the results. We would appreciate your support with ideas and specific suggestions.

closing remarks

We have the best customers in the world and are grateful for all your support.

Yours sincerely, Andreas

Project manager: Paul Küstermann

Technical manager: Volker Kröll (who is also one of our customers)

Product manager: Andreas Küstermann

Try Treesoft CAD

for free

Questions?

We're happy to help!

+49 2266 4763-800

sales@treesoft.de